Revolutionary Protection: Weld-Immune Inductive Sensors from Contrinex

Your most challenging welding applications have met their match. Weld immune inductive sensors from Contrinex provide an affordable and game-changing solution to common pain points, including enhanced protection against weld splatter accumulation, magnetic interference, and damage from moving parts.

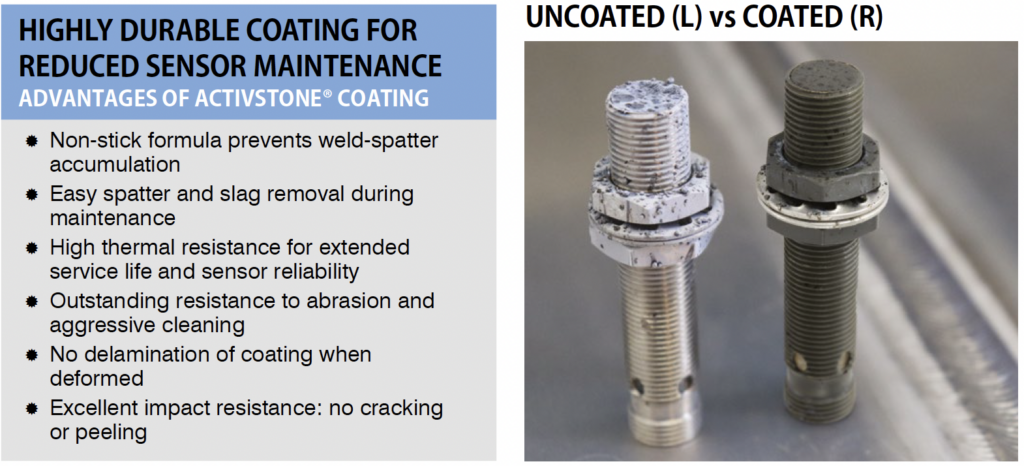

Anti-Spatter Coating

ACTIVSTONE® SX coating provides long-term protection in welding applications. This high-performance ceramic layer forms an abrasion-proof, non-stick coating on all external surfaces of the sensor, preventing weld-spatter accumulation. The coating provides exceptional robustness in MIG, MAG and spot-welding applications and withstands frequent wire-brush cleaning. Coated mounting brackets are also available.

Welding equipment typically requires frequent, aggressive cleaning using wire brushes or dry ice. ACTIVSTONE® technology ensures that the Contrinex non-stick coating is exceptionally durable, offering an extended service life. Routine maintenance is fast and easy, maximizing uptime on busy production lines.

Weld Field Immunity

Contrinex Full Inox (700) and Classics (600) technology lines meet this challenge with innovative interference-suppression designs. Sensors benefit from optimum detection sensitivity (long range) combined with immunity to magnetic interference from 50Hz fields (amplitude ≤ 40mT) and MF welding stations (current ≤ 15 kA). This delivers reliable target detection without the interruption of false triggering, and a longer sensing rage that reduces the risk of collisions.

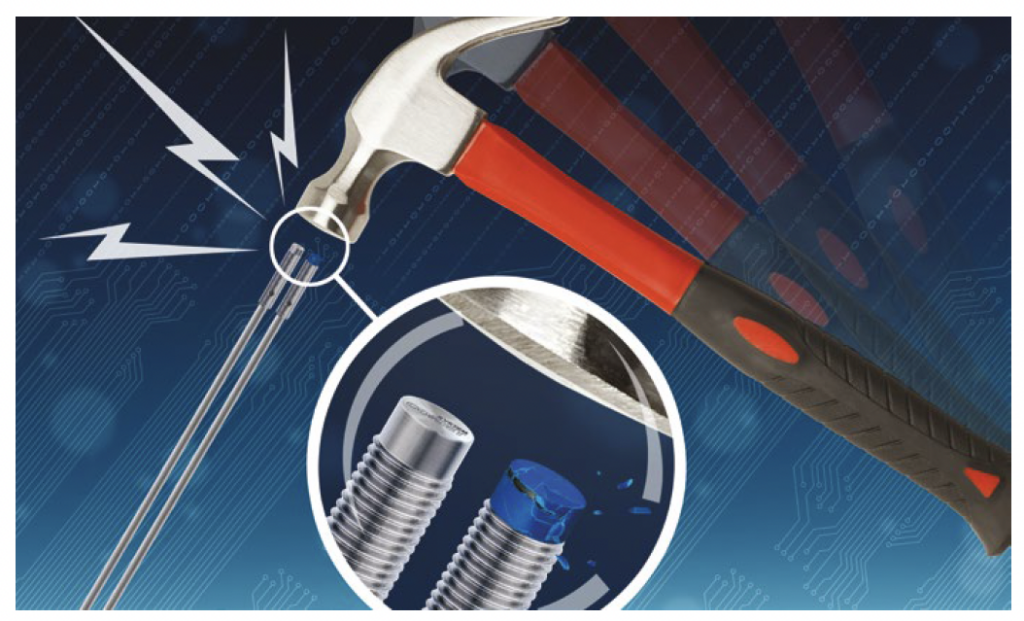

Impact Resistance

Sensors with Full Inox technology are ideal for the harshest welding environments. A one-piece stainless-steel housing (V2A /AISI 303) provides excellent chemical and mechanical resistance, withstanding extreme abrasion, shocks and vibration. Contrinex’s exclusive Condet® technology ensures sensors operate reliably even after repeated impacts.

Outstanding Protection at a Great Price

Combining Contrinex’s long-established Series 600 sensors with its ground-breaking weld immune technology gives exceptional protection at outstanding prices. Featuring a robust, temperature-resistant sensing face in a high-strength PEEK polymer and a stainless steel V2A housing, S600 weld-immune sensors are available in both ACTIVSTONE®-coated and uncoated variants. The exceptionally rugged internal construction of the S600 weld-immune range ensures uncompromising performance in the most demanding welding applications. Together with an increased operating range (≤ 8 mm), the S600 weld-immune is the first Factor 1 sensor in the Series 600 range, sensing targets in steel and aluminum equally effectively with no adjustment in sensing distance.